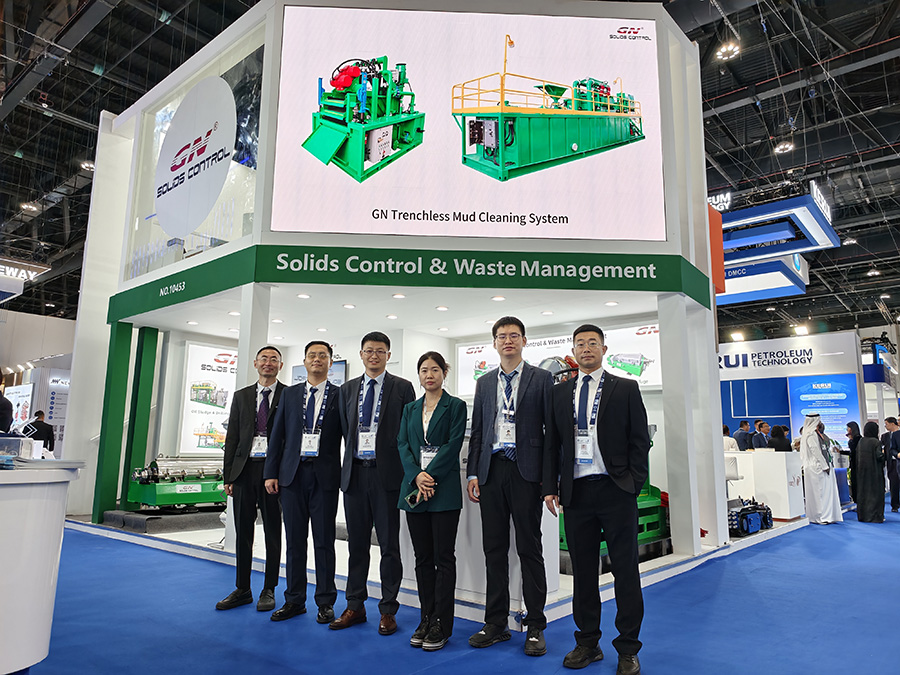

The Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC), where global oil and gas elites converge, is about to commence. GN Solids Control will demonstrate the strength of its high-end solids control equipment.

Event: Middle East ADIPEC 2025

Dates: 3-6 November

Location: ADNEC, Abu Dhabi, UAE

GN Booth No.: 10453

Products on Display: Shale Shaker for Offshore Oil & Gas and Decanter Centrifuge

Contact Email for Appointments: info@gnsolidscontrol.com

As one of the world’s top three oil and gas industry exhibitions, this edition of ADIPEC is expected to attract over 200,000 energy professionals, bringing together more than 2,200 companies and 54 national oil companies to explore the latest technologies and trends in the oil and gas sector.

01 Global Oil & Gas Event, Leading the Industry’s Future

Founded in 1984, the Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC) has grown into the most influential oil and gas exhibition in the Middle East and across Asia and Africa. It ranks among the top three oil and gas industry exhibitions globally.

This premier industry event showcases thousands of products, services, and cutting-edge technologies through various formats including conferences, technical seminars, and exhibitions. This year’s ADIPEC will host 10 specialist conferences and 350 sessions, featuring 1,600 speakers sharing industry insights. The exhibition aims to help participants enhance brand and product visibility, generate new sales opportunities, establish connections with new clients, and develop new industry partnerships.

02 GN Solids Control: An International Brand in Solids Control

GN Solids Control is a professional separation equipment manufacturer with strong technical expertise and extensive international market experience in the solids control field. The company’s main products include industrial decanter centrifuges, drilling solids control equipment, and waste management equipment. GN products serve over 70 countries and regions worldwide, having established a renowned solids control brand – GN Solids Control. The company is a solids control equipment manufacturer certified by the American API API-Q1 and CCS ISO-9001, with 70% of its products exported to international markets. GN has embarked on a path of international development, establishing subsidiaries in Houston, USA, Australia, UAE and other locations.

03 Innovative Exhibits: Focusing on Oil & Gas and Drilling Fluid Processing

At the ADIPEC exhibition, GN Solids Control will showcase two core products at booth 10453: the Shale Shaker for Offshore Oil & Gas and the Decanter Centrifuge. These equipment are specifically designed for the characteristics of oil drilling fluids, capable of completing processes such as feeding, centrifugal sedimentation, and discharge at full speed.

As the primary processing equipment in the drilling fluid solids control system, GN Shale Shakers feature high processing capacity and screening efficiency. Depending on the drilling depth, a single unit can handle flows from 90 m³/h to 180 m³/h. The equipment adopts modular and HSE design concepts, capable of meeting various requirements such as drilling fluid purification, circulation, preparation, storage, and measurement.

The GN GNLW series Decanter Centrifuge, also known as a Horizontal Spiral Discharge Sedimentation Centrifuge, is designed for separating solids and liquids in oil drilling fluids. This equipment is primarily used to recover barite in drilling mud, remove fine solids, reduce the solid content of drilling fluid, and control its density and viscosity. The GN Centrifuge series separates drilling suspension based on the principle of centrifugal sedimentation. The suspension enters the rotating bowl through the feed pipe and the discharge holes of the screw conveyor. Under centrifugal force, solid particles are pushed against the inner wall of the bowl and conveyed by the helical flights of the screw to the solids discharge ports at the conical end. The liquid phase overflows through the openings at the cylindrical end. This process continues cyclically to achieve continuous separation.

04 Technical Advantages: Professional Design Ensures Excellent Performance

GN Solids Control’s Decanter Centrifuges incorporate multiple specialized technologies, demonstrating outstanding product performance.

- The cylindrical and conical sections of the bowl are made of 2205 duplex stainless steel, formed by centrifugal casting.

- The remaining components of the bowl assembly utilize SS316L stainless steel, ensuring corrosion resistance and service life.

- The screw conveyor is protected by wear-resistant alloy plates, offering long service life and easy maintenance or replacement.

- Furthermore, the feed ports of the screw conveyor and the solids discharge ports of the bowl are protected by easily replaceable wear-resistant alloy sleeves, extending service life and maintenance intervals.

- GN Centrifuges are also equipped with positive pressure PLC intelligent explosion-proof control cabinets, facilitating automated operation and suitable for high-temperature working conditions prevalent in the Middle East.

- The use of SKF bearings enhances equipment stability and bearing lifespan.

05 Exhibition Value: A Strategic Location for Expanding in the Middle East Market

The Middle East is a crucial market for the global oil and gas industry. The UAE is the world’s third-largest holder of oil resources, with oil reserves reaching 98 billion barrels. Abu Dhabi, the capital of the UAE, holds 94% of the country’s oil reserves, amounting to 92.2 billion barrels. The Abu Dhabi National Oil Company (ADNOC) plans to increase its oil production capacity to 5 million barrels per day by 2030. To achieve this goal, the company has increased its capital expenditure plan for 2023-2027 to $150 billion and announced production expansion plans.

Participating in ADIPEC provides GN Solids Control with a valuable opportunity to connect with global energy industry leaders. It also serves as a strategic platform to showcase its technical capabilities and expand its presence in the Middle East market.

From November 3rd to 6th, at Booth 10453, Abu Dhabi National Exhibition Centre, GN Solids Control will join global energy enterprises in exploring the latest advancements in drilling fluid processing technology, working together to drive the oil and gas industry towards greater efficiency and environmental sustainability.

Visit the GN booth or email info@gnsolidscontrol.com to schedule a meeting and discuss how solids control technology can empower oil and gas extraction.

A key highlight of this unit is its innovative design, which allows the

A key highlight of this unit is its innovative design, which allows the