GN Solids Control, a leading provider of drilling fluids processing solutions, highlights its advanced Shale Shakers and Mud Cleaners, critical equipment for efficient solids control on offshore drilling platforms.

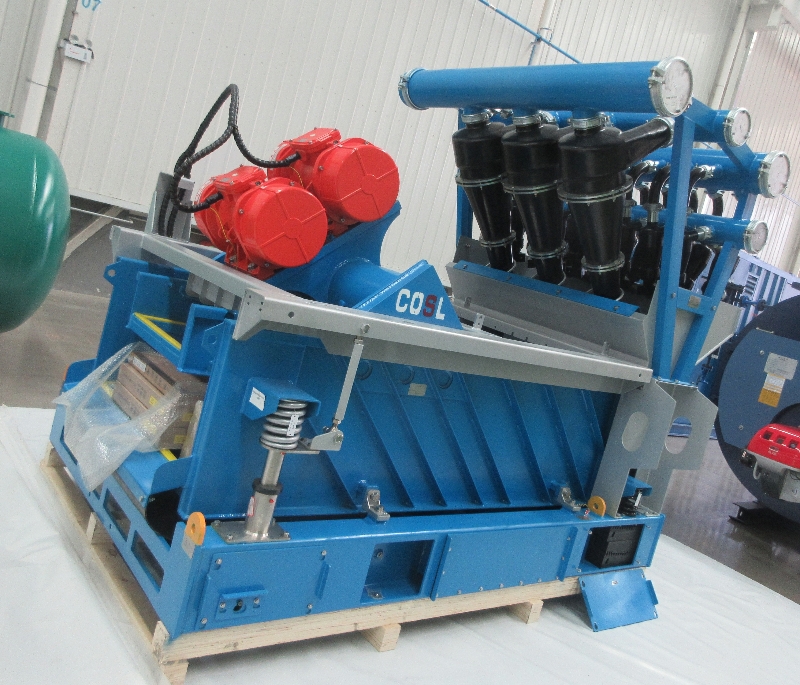

As the first phase and key equipment in the drilling mud system, the performance of the shale shaker directly impacts the effectiveness of the entire solids control system. GN Solids Control offers unparalleled flexibility, designing and manufacturing customized solutions including double or triple shale shakers mounted on a single skid, complete with integrated connecting manifolds, to meet specific client requirements for complex offshore operations.

Reflecting current industry demands, GN provides both cutting-edge options:

GNZS Linear Motion Shale Shakers: Incorporating advanced domestic and international technology with GN’s proprietary design, these shakers deliver proven performance. The complete GNZS series caters to diverse needs, with customer feedback consistently praising its advantages: high G-force for superior separation, wide screen area for increased capacity, a compact structure ideal for space-constrained offshore installations, and excellent cost-effectiveness.

Complementing its shale shakers, GN offers the GNZJ Mud Cleaner, a standard yet highly capable model. GN excels at designing customized, cost-effective Mud Cleaners tailored to unique customer needs. Whether for traditional oil & gas well drilling fluids treatment systems or specialized HDD (Horizontal Directional Drilling) Mud Recycling Systems, GN’s mud cleaners provide reliable and comprehensive solids removal.

GN Solids Control is dedicated to providing high-quality, innovative, and efficient solids control equipment and integrated solutions for the global drilling industry, with a strong focus on meeting the challenging demands of offshore operations. Our commitment to customization and cost-effectiveness ensures optimal performance for our clients’ specific applications.